Submitted by Chris Kittleson, Sr. Safety & Risk Management Consultant - Public Risk Underwriters of Florida, Inc.

Military veterans and other qualified professionals keep clear reuse water flowing at Florida’s Loxahatchee River District

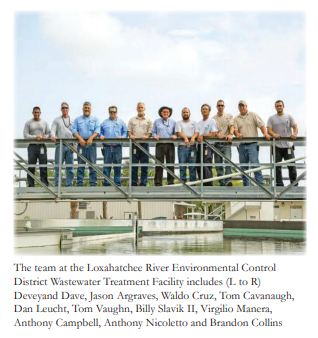

Veterans take many skills with them when they retire from the military. Many of those skills are recaptured at the Loxahatchee River Environmental Control District Wastewater Treatment Facility in Jupiter, Florida.

All five maintenance staff members are U.S. Navy veterans. “Hiring veterans is a priority here,” says Tom Cavanaugh, lead operator, day shift 2. “Our human resources manager, Tom Reynolds, a Purple Heart recipient, is ex-Army.”

The district recruits veterans through the U.S. Department of Veterans Affairs and its own website. “The core values of vets match up well with the district’s core values,” says Reynolds, who served in the infantry in Iraq from 2003 to 2008. “There’s a culture of hiring veterans here. The training and education they receive in the military matches up well with our training and education programs. They’re dedicated, work hard and ask good questions.”

Cavanaugh says the staff does most work in-house, including major projects. As a result, the plant saves money and gets the job done right: “These guys are amazing.” Albrey Arrington, district executive director, puts it this way: “We have a long history of people doing really good work. They were the folks who went before us: board members, workers with boots on the ground. It’s what sets us apart. In some places, there might be acrimony between the board and staff. Not here. Our board provides active collaborative leadership and our staff implements.”

Multiple awards are proof of the performance at the treatment plant, which produces reuse water. Recent project-ofthe-year honors have come from the American Society of Civil Engineers. The Florida Water Environment Association and the U.S. EPA have recognized the facility for outstanding operations and maintenance. EPA Region 4 honored the district with its Municipal Water Use Efficiency Award, and the collections system was rated best by the FWEA in 2016. Recently the plant received the FWEA David W. York Water Reuse Prize.

Nothing to surface waters

The district’s 72-square-mile territory includes the communities of Jupiter, Tequesta, Juno Beach and Jupiter Inlet Colony and surrounding unincorporated areas.

No water from the treatment plant is discharged to a stream. An average daily flow of 7.45 mgd is used for irrigation or injected into a deep well. Biosolids are dewatered on a pair of belt presses (Alfa Laval Ashbrook Simon-Hartley), pelletized and used for fertilizer in a joint venture with five other utilities. Pelletizing, distribution and sale of the pellets are handled by New England Fertilizer Co. (NEFCO).

The original facility was built in 1976 as a 4 mgd advanced treatment plant discharging to the Loxahatchee River, the state’s first wild river. The plant was expanded to 6 mgd in 1986, and effluent reuse was instituted. Expansions in 2000 and 2005 brought the facility to the current design capacity of 11 mgd.

fter bar screens (Parkson Corp.), the plant uses Gardner Denver diffused air blowers in an extended air configuration. That’s followed by four secondary clarifiers, enough to allow one to be taken down for maintenance. Clarified effluent goes through high-rate filtration and a Wallace & Tiernan chlorine disinfection system (Evoqua Water Technologies).

The plant has two filtration trains: traveling bridge units (now being replaced with deep-bed filters) and synthetic-media Fuzzy Filters (Schreiber), which handle the majority of the flow, about 6 mgd. The deep-bed filters will give the plant adequate nitrogen removal to meet more stringent effluent guidelines in the future, says Cavanaugh. They are being built by John J. Kirlin Construction using a design from the Hazen and Sawyer engineering firm.

Providing irrigation

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

About 80 percent of plant effluent is used to irrigate 14 area golf courses and Roger Dean Stadium, spring training home for the St. Louis Cardinals and Miami Marlins. The district also stores reuse water in some 40 acres of lakes on the plant property. “We’re really proud of the fact that we supply water for the stadium,” says Arrington.

The balance of the treated effluent is pumped into a 3,000-foot-deep well next to the plant. Reject water from nanofilters at the district’s water treatment plant across the road is also deep-welled or blended with water in the storage lakes.

torage lakes. Over the years, the plant has become surrounded by homes, condominiums and commercial businesses, so odor control is important. Evoqua supplied an odor-control system behind the biosolids dewatering building that uses caustic and sodium hypochlorite, and a biological system behind the headworks building.

Plant processes are controlled by a high-technology redundant control system employing programmable logic controllers and meters, plus a self-contained server room. “All operators are trained to run the entire plant blind, using the control system alone,” Cavanaugh says.

The facility is also prepared for emergencies, notably hurricanes. “We have two emergency generators that can run the plant when we lose power, and we have portable generator hookups on all essential components of the plant,” says Cavanaugh. “Plus, we have portable generators available to supply power to lift stations out in the field. We have power outlets in the electrical rooms so we can hook up if necessary.”

Although the area hasn’t endured a major hurricane since 2003, power outages can be daunting. “Weather is one of our major challenges,” says Arrington. “In case of major storms, we have the capacity to keep things going and prevent any overflows.” Chief operator Waldo Cruz and crew do a “fantastic job,” Cavanaugh says. “We make really good water.”

Accomplished plant team

What makes the treatment plant tick is an operations and maintenance staff that can do it all. The veteran-anchored crew, led by Anthony Nicoletto, maintenance supervisor, has achieved significant savings for the district. Reynolds points out that the veterans often bring skills and knowledge in pumps, piping and plumbing that fit right in with the district’s work.

A prime example is the dewatering building. The original plan was to tear down the existing building and erect a new one, but the in-house crew was able to retrofit the old building. They installed new girders and gussets to reinforce the structure, took off the aluminum skin and replaced it, all at considerable savings.

In another case, the staff cut apart and removed a lime silo no longer in use because solids were no longer being landapplied or landfilled. The in-house team also cleans the aeration basins, equalization tanks and clarifiers, including sand removal, sandblasting and painting. “We also have a couple of guys who are expert welders,” Cavanaugh says. “They can weld anything. It’s really amazing.”

Another staffer, Ross Cowell, is an expert in pumps. He built an oven so he could bake on the lacquer needed for the copper wiring on pump motors. “In addition, we have a great metal fabrication team, so we can build just about anything in our shop,” says Cavanaugh. Bob Ward adds electrical expertise. Jason Argraves is safety and compliance officer, responsible for trench training and safety training.

Cavanaugh also lauds the laboratory staff: “They’ve provided the most extensive and complete record of water quality in the Loxahatchee River over nearly 40 years of regular testing and monitoring, as well as monitoring treatment plant performance.”

The culture of economy extends to the collections department, where the district shares two Vac-Con combination trucks with neighboring utilities. The savings are annually reported to the district board, with the pleasant result that sometimes bonuses have been paid to the staff.

Diligent training

The district also handles training in-house to save money and time. “We concentrate on on-the-job training, but the plant also has a training room where we do testing for licenses in-house, and conduct training for CEUs,” Cavanaugh says.

Cross-training is critical. Maintenance workers join the operational staff at times, and vice versa. Plant staffers also exchange with collections workers, learning how to drive the cleaning trucks and handle other tasks.

“PLC training is conducted by the district’s IT staff, and training for hazardous activities is handled by the fire department’s hazmat team just down the road,” Cavanaugh says. Arrington understands the value of these activities: “There’s no silver bullet, but the better your people are, the more efficiently everything works. I’m a big fan of the TV program Undercover Boss. Not all ideas are home runs, but our staff has good ones. Collaboratively, we get better as an organization.”

As with all plants, even those with several award plaques on the wall, the future presents challenges. “We have challenges across the board: money, staffing, regulations,” says Arrington. “We strive to maintain high performance, permit compliance and minimal odors. The challenge is doing all things cost-effectively.” To Cavanaugh, the goal is even more explicit: “We are in charge of keeping the river clean.”

Whatever the task at hand, the seven Navy and two Army veterans on the staff are a perfect fit. “Just like in the service, there’s a brotherhood here,” says Reynolds. “We’ve got each other’s back.”

Teaching tools

Few clean-water plants can actually show visitors the quality of the water they produce the way the staff can at the Loxahatchee River District. Here, visitors can step onto a viewing platform and view some 40 acres of lakes that contain the plant’s reuse water. They’ll also see ducks and migrating birds.

“People take pictures, and wildlife photographers use it to get dramatic shots of birds in flight,” says Tom Cavanaugh, lead operator. Right next door is the Busch Wildlife Sanctuary, a free public zoo containing fish, alligators and birds. Wildlife expert Jack Hanna comes in once in a while for educational demonstrations. The parking lots are always full.

The zoo also refers to the treatment plant with an interactive diagram showing how water passes from homes and businesses to the plant and then to the reuse lakes. “We give plant tours all the time,” says Cavanaugh. “As many as 250 people last year. We get a lot of students from elementary school to college level. Recently, we’ve had 15 to 20 students a month from Florida Atlantic University.”

Wastewater treatment is also featured at the Loxahatchee River Center a few miles from the plant. Supported by Friends of the River, the center shows the flow of the river from its headwaters, through the cypress-dominated floodplain, and across the sandbar into the coral reefs. A number of aquariums and interactive displays teach visitors about water quality and solutions for preserving the river in the face of growing population and development.

This article first appeared in the January 2017 issue of Treatment Plant Operator magazine, published by COLE Publishing, Three Lakes, Wisconsin. It is reprinted by permission.